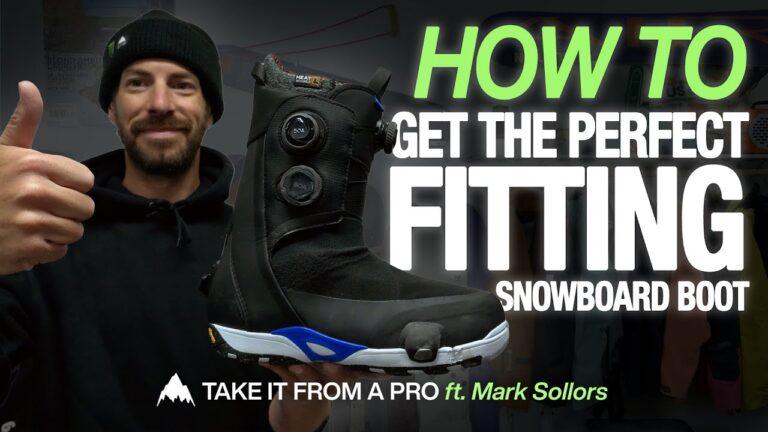

If you want your Burton boots to fit perfectly and feel comfortable from the first step, heating and molding them is the key. But how exactly do you heat mold Burton boots to get that custom fit without damaging them?

You might be wondering if it’s complicated or if you need special tools. Don’t worry—this guide will walk you through simple, effective steps to heat mold your boots right at home. Keep reading, and you’ll learn how to unlock the full potential of your boots, making every ride smoother and more enjoyable.

Why Heat Mold Burton Boots

Heat molding Burton bootshelps make them fit your feet better. This process softens the boot’s shell, allowing it to shape perfectly to your foot. It improves comfort and support during snowboarding.

Benefits include:less pain, better control, and fewer hot spots. Heat molding also reduces foot fatigue, helping you ride longer with less discomfort.

Heat mold your bootswhen they feel too tight or too loose. New boots often need molding to match your foot shape. Also, if you change foot size or notice pressure points, it’s time to heat mold.

Credit: www.powder.com

Tools Needed For Heat Molding

Essential equipmentfor heat molding Burton boots includes a heat gun or a boot dryer. A heat gun provides controlled, even heat to soften the boot material. A boot dryer can also warm the boots gently. Use thick gloves to protect your hands from burns. A clean cloth helps wipe off any moisture after heating. A flat, clean surface is needed to place the boots while molding.

Safety precautionsare very important during heat molding. Always wear gloves to avoid burns. Keep the heat source moving to prevent damage. Do not overheat the boots; too much heat can ruin them. Work in a well-ventilated area to avoid breathing in fumes. Keep children and pets away during the process.

Preparing Your Boots

Start by cleaning your bootsto remove dirt and debris. Use a soft brush or cloth to wipe off mud and dust. Dry them completelybefore heating. Damp boots will not mold properly.

Next, carefully remove the linersinside your Burton boots. This step helps the heat reach all parts of the boot evenly. It also protects the liners from damage during heating.

Place liners in a dry area away from direct heat. Let boots air dry if they are still wet. This preparation ensures better molding resultsand comfort.

Heat Molding Methods

Using a boot heateris a safe way to heat mold Burton boots. The heater warms the boots evenly without damage. Place boots in the heater and follow the manufacturer’s instructions. This method softens the liner to fit your feet better.

The oven methodneeds care. Preheat oven to a low temperature, about 150°F (65°C). Put boots on an oven-safe tray. Heat them for 5-7 minutes only. Too much heat can ruin boots. After heating, wear the boots until they cool down. This helps shape them to your feet.

Professional heat molding servicesoffer expert fitting. Specialists use tools and heat to mold boots perfectly. This service costs more but ensures the best fit. It is ideal for those unsure about home methods or wanting precise shaping.

Step-by-step Heat Molding Process

Start by heating your Burton boots in a boot heateror oven made for this purpose. Keep the temperature around 200°F (93°C). Heat for about 5-10 minutesuntil the boots feel warm but not hot. Avoid overheating to protect the materials.

Next, wear the boots immediately after heating. Put on your ski socksto get the right fit. Stand or walk gently to shape the boots to your feet. This helps create a custom fitthat improves comfort and control.

Allow the boots to cool downwhile wearing them. Cooling locks the shape inside the boots. Keep them on for at least 20 minutesor until fully cool. This step ensures the boots fit perfectly.

Credit: www.youtube.com

Common Mistakes To Avoid

OverheatingBurton boots can cause damageto the material. Heat boots slowly and check often. Too much heat may warpor weakenthe boots.

Incorrect timingleads to poor fit. Boots need enough time to mold but not too long. Follow the manufacturer’s instructionscarefully to get the best result.

Ignoring safetycan cause burns or fire. Always use heat sources that are safeand keep boots away from open flames. Use gloves to protect your hands from hot surfaces.

Maintaining Molded Boots

Store molded bootsin a cool, dry place to keep their shape. Avoid direct sunlight and heat sources that can warp the boots. Use boot trees or stuff them with paper to help maintain their form. Keep boots away from moisture to prevent mold and damage.

Re-molding boots may be needed if they lose shape or feel uncomfortable. Warm water or a heat gun on low setting can soften the material. Gently reshape the boots with hands or by wearing them while warm. Always let boots cool down naturally to set the new shape.

Credit: www.dcshoes.com

Troubleshooting Fit Issues

Too tight bootscause discomfort and pain. Heat molding helps soften the boots. Wear them with thick socks while molding for a better fit. Too loose bootscan cause blisters. Add insoles or thicker socks to fill space. Pressure points often appear near the toes or heel. Use a boot pad or foam to ease these areas. After molding, boots may still need small adjustments. Heat again gently for problem spots. Let boots cool while worn to keep the shape. Repeat the process slowly for best comfort. Always test boots by walking before long use.

Frequently Asked Questions

How Do I Heat Mold Burton Boots At Home?

To heat mold Burton boots, use a boot heater or warm water. Heat softens the liners, allowing a custom fit. Follow Burton’s instructions carefully to avoid damage. Heat molding improves comfort and performance by conforming boots to your feet.

Can I Use An Oven To Heat Mold Burton Boots?

No, avoid using an oven to heat mold Burton boots. Excessive heat can damage materials and affect boot performance. Use recommended methods like boot heaters or professional heat molding services for safe and effective results.

How Long Should I Heat Mold Burton Boots?

Heat mold your Burton boots for about 5 to 10 minutes. This duration softens the liners enough to mold to your feet. Follow specific model guidelines to ensure the best fit without overheating or damaging the boots.

Is Heat Molding Necessary For Burton Snowboard Boots?

Heat molding is highly recommended for Burton snowboard boots. It ensures a personalized fit, increasing comfort and control on the slopes. Properly molded boots reduce pressure points and improve overall snowboarding performance.

Conclusion

Heating mold Burton boots helps improve comfort and fit. Use warm air or heat pads carefully and evenly. Avoid overheating to protect the boot material. Take time and check the fit often during the process. Proper heating can extend your boots’ life and performance.

Enjoy better support and warmth on every ride. Small steps lead to great results. Keep your boots cozy and ready for the slopes. Simple care makes a big difference in comfort.

Madison Clark is a footwear expert and the voice behind MyStyleGrid.com. She specializes in honest shoe reviews, style tips, and practical guides to help readers find the perfect pair for any occasion. With years of experience in blogging and content creation, Madison makes footwear knowledge simple, stylish, and easy to follow.